Aktualności

Works on launching the odor reduction system have started

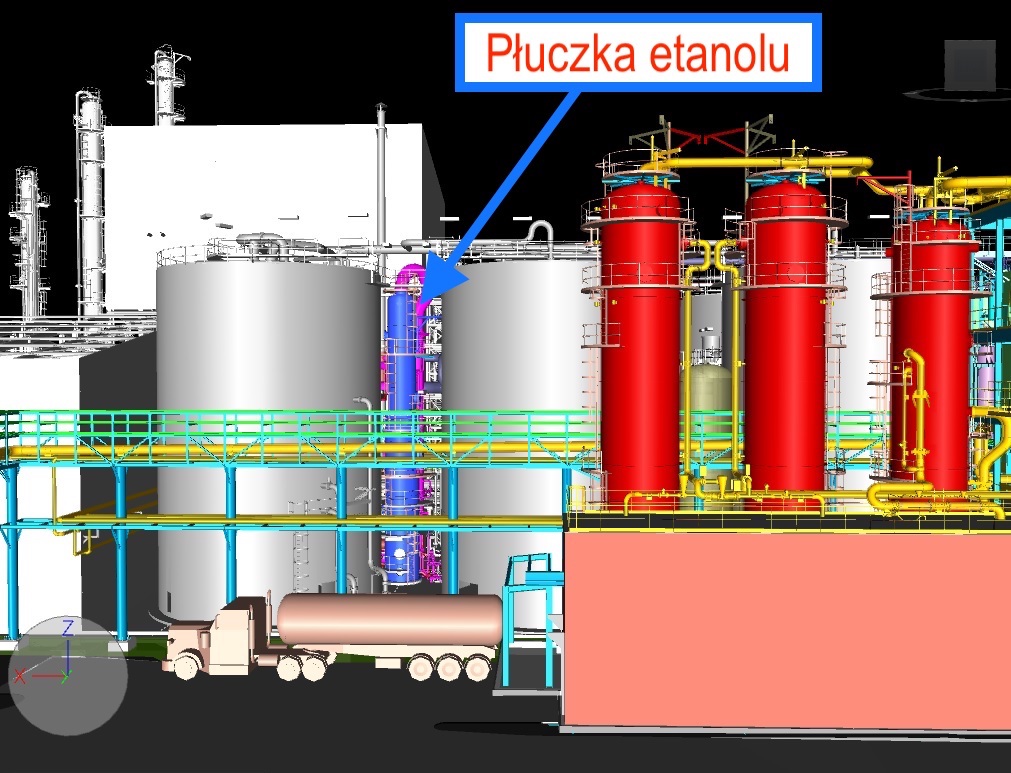

Bioagra SA is preparing the assembly of ethanol scrubber, which is part of the odor reduction system arising from the production of ethanol. This week, the company turned off part of the installation to prepare a place where a nearly 20-meter device weighing almost 30 tons will stand.

The fermentation odor reduction system was developed by a team of Polish and American experts commissioned by Bioagra SA. A solution consisting of the so-called ethanol scrubbers and catalytic oxidation equipment was created based on research conducted in and around the plant. The ethanol scrubber, the first element of the system, has already been practically built and in a few weeks will arrive by special road transport to the “Goświnowice” Ethanol Plant. The company must now prepare the foundations for a structure weighing nearly 30 tons.

The installation of the scrubber, according to the plan, should take place at the end of April this year. Next month, testing and calibrating the installation with a new device will be conducted. This is a key operation for the proper functioning of the entire system. The scrubber’s task is to condense the maximum amount of ethanol rising from the fermentation vats and return it to the technological process. This will allow effective reduction of alcohol vapors and will enable the implementation of the second stage of the investment, which will be the construction of a catalytic oxidation device. According to specialists, the solution will help to eliminate the characteristic smell that comes from the fermentation process. It can be felt inside and around the plant depending on weather conditions.

Bioagra SA has been running a program to reduce its impact on the environment since 2018. The company has implemented measures despite the fact that it produces ethanol in accordance with the standards in force in both Poland and the European Union. The company’s management has guaranteed the local community that it will commission the development of solutions that will permanently reduce the intensity of smell and sound generated in the production of ethanol.

Only recently has Bioagra SA allocated over PLN 8 000 000 for this purpose. The company silenced the grain elevator tower windows and fans at its top last November. Specially designed sound suppressors were mounted on them. Before that, the company replaced a new part of production equipment, and also modernized the infrastructure for unloading corn grain, which reaches the plant by railway wagons. The corn grain cleaning line was also modernized to move the loading of the so-called chaff into the plant and reduce the volume of sound propagating towards Goświnowice. For the same purpose, foundations that will extend the elevator line and provide a natural sound screen have been poured into new grain tanks in recent months.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.