Category: aktualności- strona główna

Aktualności

Bioagra planted 2 600 trees

Within two years, Bioagra SA planted nearly 2 600 trees around the “Goświnowice” Ethanol Production Plant. When they grow, they will act as a barrier to the sound generated by the plant and improve the aesthetics of the space.

The scale of the project is very large. This year, Bioagra will plant more trees in the vicinity of ZPE than Rzeszów in the entire city, with a population of nearly 200 000. The cost of planting, without ongoing maintenance, i.e. watering and protection, has amounted to a total of approx. 275k PLN

The company has been planting trees intensively since 2018. Seedlings from 1.5 to 4 meters high were used to create a green wall around the plant. The trees are to improve the aesthetics of the factory surroundings in summer and winter, as well as contribute to reducing the noise level from the production installation.

This year, the company plans to plant nearly 1,200 trees and further enhance biodiversity. So far, mainly conifers have been planted. However, new plantings of deciduous trees, such as linden or hawthorn, will appear in the fall.

Aesthetic trees resistant to weather conditions, diseases and pests were selected for planting. At the moment there are Serbian spruces, blue spruces, black pines, alumi cypresses and thujas “Sarbina”, “Kórnik” and “Brabant”.

The green wall of trees is just one of the elements of BIOAGRA SA’s activities aimed at reducing the noise generated by the production installation. In addition to planting, a number of other activities were carried out on the site. The loudest and most acoustically disturbing devices were located.Various silencers were installed, the devices were replaced with new ones and natural acoustic walls in the form of grain tanks were built. Further activities of this type are planned.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Queens at Bioagra

Beata Malik, a beekeeper from Skorochów near Nysa, runs a bee breeding project in cooperation with Bioagra. In several dozen so-called mating boxes, standing at company’s premises, bees are preparing for mating flights. Classic hives, at which bess laboriously produce honey, are standing next to mating boxes.

The mother bee breeding program has now been running for the third season and brings very good results. New queens and their descendants, bee families, are gentle and hard-working thanks to proper breeding that enables proper gene exchange between insects.

The area that was made available by Bioagra is closed and monitored. Bees live peacefully and have a large supply of varied food under the watchful eye of cameras. Rapeseed fields, acacia, linden and forests are all within the range of flights of insects.

In such a favorable environment, young bee mothers are getting ready for their future role – the queen of the entire bee family. They stay in special hives, the so-called mating boxes. From here they set off for a mating flight. Young queens are replacing the old ones or are introduced into the hive in case the old queen dies.

– We were looking for an area where bees do not disturb people and people do not disturb bees – says Beata Malik, who runs an apiary. – Cooperation with Bioagra is perfect for the bees. The environment in which the hives stand is very clean. The company informs us in advance when works related to its activities will be carried out and we can rearrange the hives if there is such a need.

On one hand, Beata Malik treats cooperation with Bioagra as a support for local business, but also as an activity of great importance for bees as a species. In order to survive they need healthy, genetically strong queens that allow the insects to extend the species. In turn, people, thanks to bees, receive honey and something of extraordinary value. It is about the possibility of growing many plants that are a key link in the food production chain.

According to the United Nations, bees pollinate about 70 out of 100 crops that provide 90% of humanity. food. It is estimated that a third of food eaten by humans is created thanks to the fact that bees pollinate the flowers of various plants. “If the bees would disappear, humanity would not have survived four years …” – this statement, attributed to Albert Einstein, indicates the importance of the role of bees in the production cycle of food that we buy in stores.

It is estimated that about 470 species of bees live in Poland. Over half of them are threatened with extinction. As Beata Malik explains, bees currently don’t have enough places where they can live safely, reproduce and obtain food. Beekeepers have more and more problems with setting the hives. Like other breeders, e.g. cows, goats or pigs, they are often reluctant to be seen in inhabited places.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Action addressed to the local community

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

How to effectively increase security?

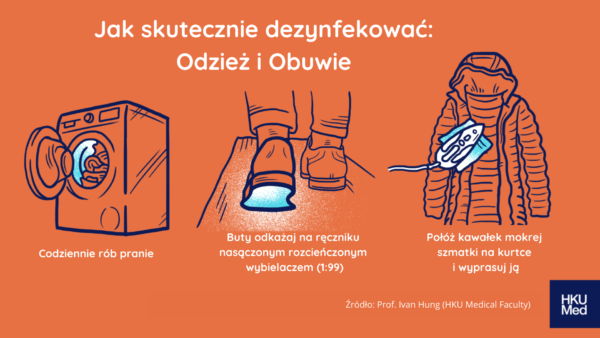

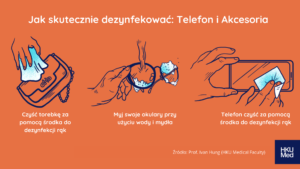

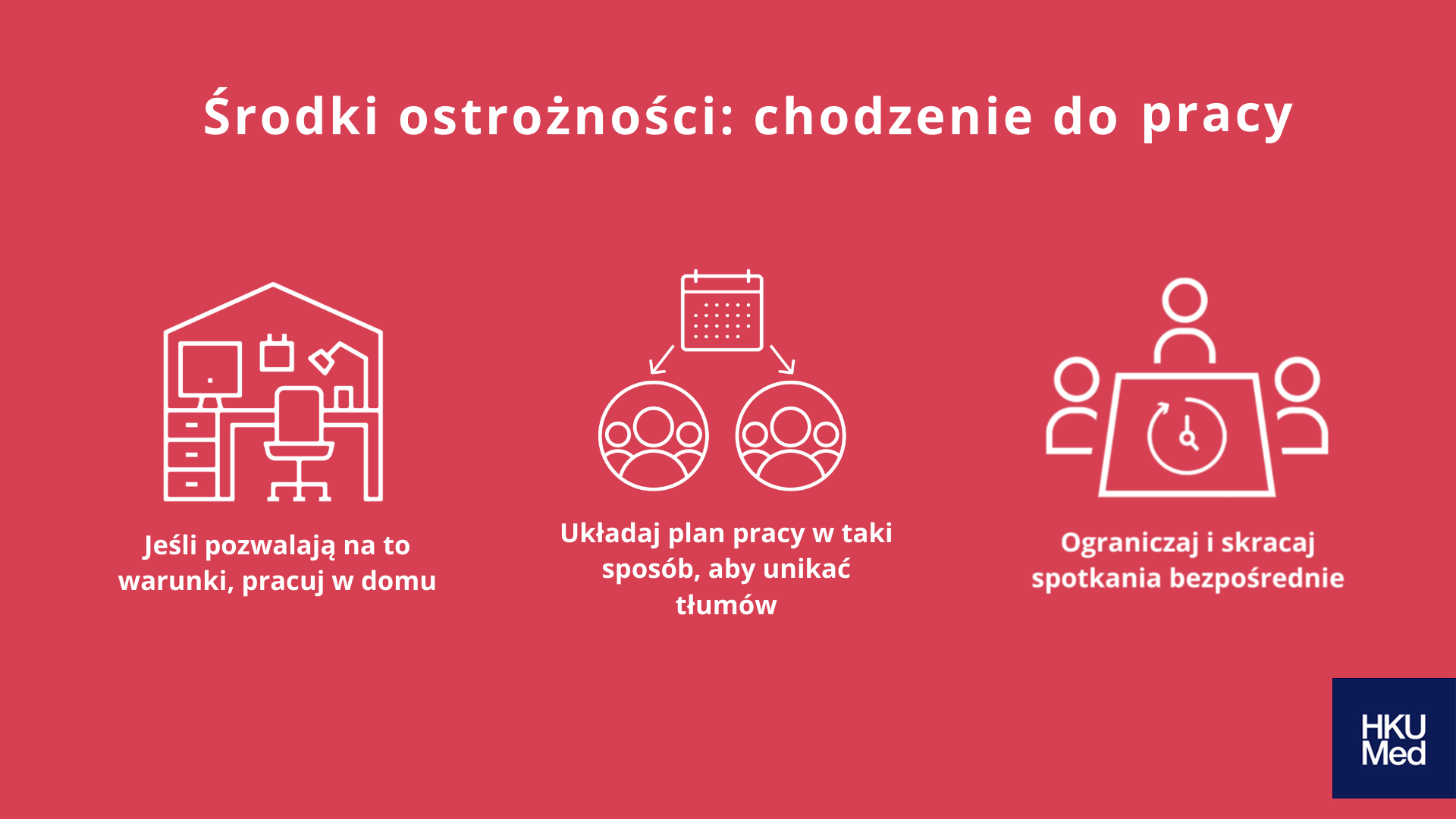

To reduce the risk of coronavirus (COVID-19) spreading and increase your own safety at home and work, use the well-known recommendations of the Chief Sanitary Inspectorate. It is also worth to take advantage of the recommendations developed by the Medical Department of the University of Hong Kong (presented below in the form of infographics).

In the last few decades, the inhabitants of Asia have survived several major viral epidemics (bird flu and swine flu and SARS).

At the same time, they developed behaviors and habits that help significantly increase safety and avoid contact with various types of viruses, including coronavirus.

You can fight the virus successfully by implementing these few additional, simple rules regarding personal hygiene and people-to-people approaches.

Hong Kong has a population of 7.5 million. They live on an area only twice as large as that occupied by Warsaw, in which 1.8 million people live.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Nomination for the Tryton Nyski award

Arkadiusz Komorowski was nominated for the Tryton Nyski honorary distinction in this year’s 22nd edition of this prestigious competition. The director of ZPE “Goświnowice” was nominated as the originator of revitalization of the Old Mill in Nysa and a unique program for reducing sound and smell generated in the production of ethanol.

The Tryton Nyski honorary distinction is an expression of the highest recognition of the local community and is awarded to persons, organizations and institutions particularly distinguished for the Nysa commune.

– All my adult professional life is related to Nysa and this region – said Arkadiusz Komorowski during the awarding gala. – We are proud that we can develop the plant in a sustainable way – taking care of environmental protection and in harmony with the local community. We are increasing production, increasing the number of jobs in the plant and its surroundings in many market segments – added Arkadiusz Komorowski.

– All my adult professional life is related to Nysa and this region – said Arkadiusz Komorowski during the awarding gala. – We are proud that we can develop the plant in a sustainable way – taking care of environmental protection and in harmony with the local community. We are increasing production, increasing the number of jobs in the plant and its surroundings in many market segments – added Arkadiusz Komorowski.

Bioagra has already invested nearly PLN 20,000,000 in sound and smell reduction. As a result of these and subsequent activities, the company will soon become one of the most ecological plants at the European level and will produce completely new products.

Arkadiusz Komorowski is also the originator of the revitalization of the Old Mill in Nysa, a building that has not been used for years. The investment will be completed in 2021. The building will combine office, recreational and residential functions – there will be service and catering premises on the ground floor , a conference room, and apartments on the upper floors.

After revitalization, the main attraction of this place will be a fountain symbolically reproducing the course of the river driving the mill wheel. It will stand on the town square in front of the Old Mill. A parking lot for nearly fifty spaces has been planned next to it, which will be available to the residents of Nysa.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Super foam from Bioagra

Bioagra transferred a specialized extinguishing agent worth about PLN 50,000 to Nysa fire brigade. It is a Formula 1 car in its field – indicates the company. It is used to extinguish solids and liquids, e.g. gasoline, petroleum, alcohol, and even jet fuel.

The extinguishing agent passed by Bioagra is highly specialized. It is used to produce an aqueous solution from which various types of foam can be obtained. It will last for plenty extinguishing actions.

– The agent should be enough for a long time, because it is most often used to extinguish small fires – says Marcin Skalny, junior foreman from KP PSP in Nysa. – Last year, such fires accounted for 93% of all fires in our county. – The extinguishing agent can be successfully used for various types of extinguishing operations, including protection of spilled flammable liquids, e.g. car fuels in actions on roads or railways.

The agent provided by Bioagra is widely used. It can be used simultaneously with extinguishing powder mixed with foam and other extinguishing foams. Due to its unique properties, it is very useful when extinguishing liquid fires, which destroy extinguishing foam produced from other universal foaming agents. It can be used to make foam in combination with tap water, industrial water and even sea water.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.