Category: Uncategorized

Aktualności

Mr. Corn at the Nysa Run

Mr. Corn once again opened the “Family Mile” and Nysa Run, which took place on June 8, 2019. The 7th edition of the event gathered a record number of nearly 900 competitors from Poland and abroad at the start.

Parents and their children appeared an hour before the main race at the start of the so-called “Family Mile” – a free event for everyone, with no age restrictions. The organizers also prepared additional attractions for Nysa families. This year, as before, Mr. Corn, a mascot of Bioagra SA, enjoyed great interest. Polish Olympic athletes from Moscow, Urszula Kielan and Janusz Trzepizur also ran in “Family Mile”.

The competitors covered a distance of 10 km in the Nysa Race. Kamil Karbowiak from Kotwica Brzeg won – he has ran this distance in 30 minutes and 20 seconds. It was a surprising change after the band of successes of players from Kenya. This year, the second and third place were taken by Hosea Tuel and Moses Kibire, and the fourth – another nice surprise – was taken by Paweł Matner from Matner Running Team Nysa. Like a year ago, a large group of professional runners, as well as entire groups practicing semi-professionally from Opole and other regions of the country stood on the starting line. Many participants are people who treat running as a form of active leisure. For them, beating the route was a test of speed and endurance in the struggle with professionals who impose a very fast pace from the very beginning.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Bioagra increases employment

In connection with the development of its operations, Bioagra SA is looking for people to work at the Ethanol Plant “Goświnowice” near Nysa, for the following positions: Mechanics-hydraulics – 2 employees, Chief Mechanic Specialist for ZUR – 1 employee, Finished Goods Warehouse Worker – 8 employees , Quality controller, laboratory employee – 2 people.

Bioagra offers, among others, employment under a contract of employment, specialized training, the opportunity to learn English and private medical care at LUXMED.

We expect higher technical education, mechanical direction and machine construction from the Chief Specialist of Mechanics for ZUR. The candidate must have energy licenses up to 15 kilovolts and several years of experience in maintenance services.

An employee of a finished goods warehouse may have vocational or secondary education, but most important are strong computer skills, including proficiency in MS Office.

A quality controller, laboratory worker, should have a university degree in chemistry or related education. You should show good computer skills and knowledge of MS Excel. A year of experience working in a similar position is welcome.

A mechanic-plumber should have a technical secondary (mechanical) education, energy qualifications, the ability to read technical drawings, experience in a similar work place for a minimum of 1 year and a category B driving license.

Bioagra SA is currently Poland’s largest producer of bioethanol and ethanol produced from corn grain. The company’s production plant, which is located near Nysa, is one of the largest employers in the region. Nearly 150 people work there. A much larger number of people find jobs in the company’s economic environment, including in the services and storage sector, transport and agriculture. The company was awarded in the Employer of the Year competition by the Nysa County in the category of medium and large enterprise. In its selection, the chapter was mainly guided by the state and stability of employment in enterprises, the amount of average employee remuneration, innovation and charity.

The company also cooperates with nearly 1,400 farmers and agricultural companies from all over the country. As many as 700 of them come from the Opolskie Voivodeship and satisfy nearly 40% of company’s demand for corn grain.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Bioagra supports safety

Two tons of feed materials and prepaid cards with Mr. Corn were funded by Bioagra SA for the winners of the 17th National Competition “Safe Farm” and the 8th edition of the art competition for children, entitled “The machine works but the child watches.” Both contests are regularly organized by the Agricultural Social Insurance Fund (KRUS).

Both competitions have an important social aspect – their goal is to promote farm security, including child safety.

“Safe Farm” is one of many preventive actions of the Agricultural Social Insurance Fund (KRUS) in the improvement of occupational health and safety on farms. The competition was organized in cooperation with the Ministry of Agriculture and Rural Development as well as the National Labor Inspectorate and the National Center for Agricultural Support, the Agency for Restructuring and Modernization of Agriculture. The honorary patronage was taken by the President of the Republic of Poland Andrzej Duda. Art competition for children “The machine works but the child observes”, whose patron was Jan Krzysztof Ardanowski, the Minister of Agriculture and Rural Development, is organized to promote positive behavior related to the work and play of children on the farm among schoolchildren from primary schools in rural areas.

The competition also popularizes the “List of particularly dangerous activities related to running a farm”, which must not be entrusted to children under 16 years of age. This year’s competition slogan: “Safe in the countryside: the machine works but the child watches” is to draw attention to the ways of preventing accidents related to the presence of agricultural machinery and equipment on farms. The young authors of the winning entries received payment cards with Mr. Corn, each worth PLN 100.

When assessing farms in the ‘Safe Farm’ competition, the jury took into account the organization of the farm bypass and yard, order within the yard, buildings and work stations, technical condition of livestock and farm buildings, technical condition of machines, devices and tools used on the farm, conditions of handling and living of farm animals, equipping with work clothes and personal protective equipment, storage of plant protection products and other hazardous substances. The jury also took into account the aesthetics of farms, applied organizational, technological and technical solutions affecting the safety of people working and staying on a farm.

The safest farm in the Nysa poviat was the farm of Dorota and Waldemar Rusek from Otmuchów. The farm of Rose and Robert Przywar from Prusinowice, Pakosławice commune was also awarded. Each of them received a ton of feed materials.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

The next step on the way to reducing odor

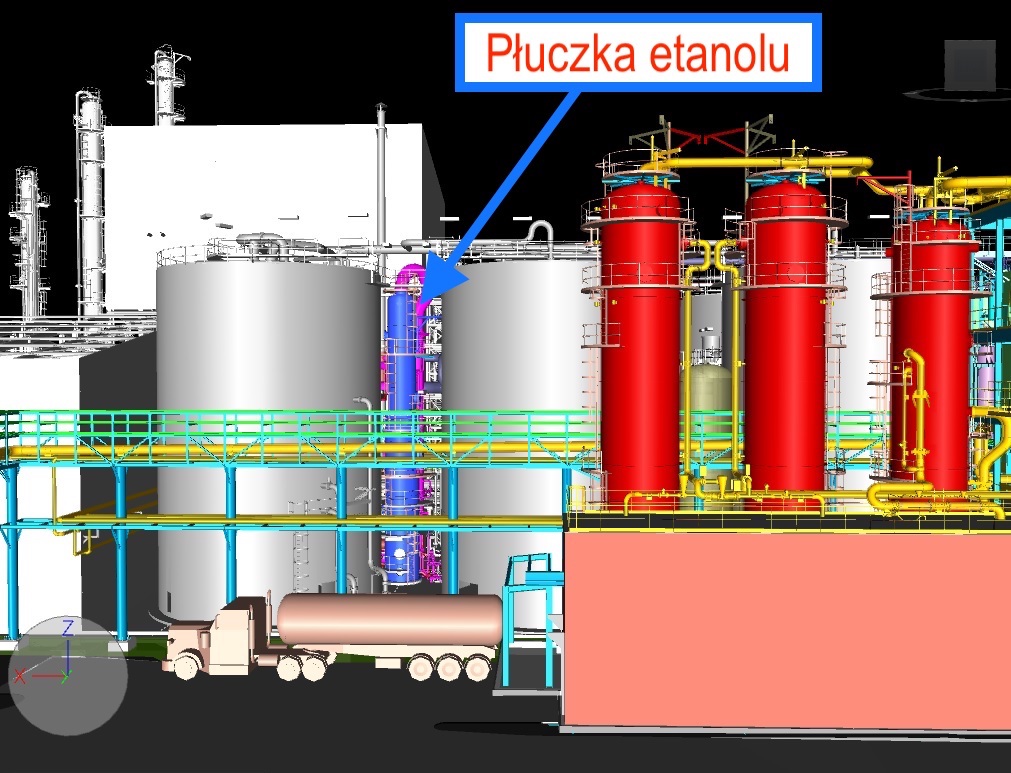

Bioagra SA has set up the so-called absorber, the first part of the system for reducing the intensity of aroma generated in the production of ethanol. In this complicated operation – the device measures nearly 20 meters and weighs almost 30 tons – a dozen or so people and two specialized cranes participated.

The absorber, also known as ethanol scrubber, developed at the request of the company by a team of Polish and American experts, was set up very efficiently. Despite the fact that it weighs several dozen tons and its target location is practically the interior of the production complex. To carry out this operation, two cranes were used, which together lifted the device from the truck. Then, specialized equipment with a lifting capacity of 70 tons took over the weight of the absorber and lifted it above the roofs of the plant. Then he slowly lowered the washer between the components of the installation onto the previously prepared foundation with special fixings.

In the coming weeks, the ethanol scrubber will be included in the technological process. Testing and calibrating the installation with a new device will be conducted next month. This is a key operation for the proper functioning of the entire system. The scrubber’s task is to condense the maximum amount of ethanol rising from the fermentation vats and return it to the technological process. This will allow for effective reduction of alcohol vapors and enable the implementation of the second stage of the investment. It will be the construction of a catalytic oxidation device. According to experts, the solution will help to eliminate the characteristic smell that comes from the fermentation process. It can be felt inside and around the plant depending on weather conditions.

Bioagra SA has been running a program to reduce its impact on the environment since 2018. The company has implemented measures despite the fact that it produces ethanol in accordance with the standards in force in both Poland and the European Union. The company’s management has guaranteed the local community that it will commission the development and implementation of solutions that will permanently reduce the intensity of smell and sound generated in the production of ethanol.

Only recently has Bioagra SA allocated over PLN 8 000 000 for this purpose. The company silenced the grain elevator tower windows and fans at its top last November. Specially designed sound suppressors were mounted on them. Before that, the company replaced a new part of production equipment, and also modernized the infrastructure for unloading corn grain, which reaches the plant by railway wagons. The corn grain cleaning line was also modernized to move the loading of the so-called chaff into the plant and reduce the volume of sound propagating towards Goświnowice. For the same purpose, foundations that will extend the elevator line and provide a natural sound screen have been poured into new grain tanks in recent months.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

Works on launching the odor reduction system have started

Bioagra SA is preparing the assembly of ethanol scrubber, which is part of the odor reduction system arising from the production of ethanol. This week, the company turned off part of the installation to prepare a place where a nearly 20-meter device weighing almost 30 tons will stand.

The fermentation odor reduction system was developed by a team of Polish and American experts commissioned by Bioagra SA. A solution consisting of the so-called ethanol scrubbers and catalytic oxidation equipment was created based on research conducted in and around the plant. The ethanol scrubber, the first element of the system, has already been practically built and in a few weeks will arrive by special road transport to the “Goświnowice” Ethanol Plant. The company must now prepare the foundations for a structure weighing nearly 30 tons.

The installation of the scrubber, according to the plan, should take place at the end of April this year. Next month, testing and calibrating the installation with a new device will be conducted. This is a key operation for the proper functioning of the entire system. The scrubber’s task is to condense the maximum amount of ethanol rising from the fermentation vats and return it to the technological process. This will allow effective reduction of alcohol vapors and will enable the implementation of the second stage of the investment, which will be the construction of a catalytic oxidation device. According to specialists, the solution will help to eliminate the characteristic smell that comes from the fermentation process. It can be felt inside and around the plant depending on weather conditions.

Bioagra SA has been running a program to reduce its impact on the environment since 2018. The company has implemented measures despite the fact that it produces ethanol in accordance with the standards in force in both Poland and the European Union. The company’s management has guaranteed the local community that it will commission the development of solutions that will permanently reduce the intensity of smell and sound generated in the production of ethanol.

Only recently has Bioagra SA allocated over PLN 8 000 000 for this purpose. The company silenced the grain elevator tower windows and fans at its top last November. Specially designed sound suppressors were mounted on them. Before that, the company replaced a new part of production equipment, and also modernized the infrastructure for unloading corn grain, which reaches the plant by railway wagons. The corn grain cleaning line was also modernized to move the loading of the so-called chaff into the plant and reduce the volume of sound propagating towards Goświnowice. For the same purpose, foundations that will extend the elevator line and provide a natural sound screen have been poured into new grain tanks in recent months.

Inne aktualności

AKTUALNOŚCI | 24.12.2018

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region.

Aktualności

10 story Mr. Corn

Bioagra has launched probably the largest Christmas illumination in the region. Mr. Corn, the company’s mascot wishes everyone “Merry Christmas” from the wall of the 10-story grain elevator in the Ethanol Plant “Goświnowice”.

This year, Mr. Corn warmed up the participants of such events as the Nyski Run and Otmuchowski Independence Run and entertained the little ones during harvest festival and Children’s Day events. This time, Bioagra used its company mascot – literally – on a large scale. At nearly 10 floors high, Mr. Corn towers over the area at night in the form of illuminations on the wall of a grain elevator.

The elevator, which was created in the 1970s, is one of the tallest buildings in the region. The structure itself measures 33 meters in height, while the tower located in the central part is 10 meters higher. The creation of an elevator contributed to the development of agriculture in this part of the Opole region. The facility was modernized during the construction of the “Goświnowice” Ethanol Plant.

Bioagra is currently running another facility modernization program. In November this year it silenced the grain elevator tower windows, as well as fans placed on top of it. Specially designed sound suppressors were mounted on them. Before that, the company replaced a new part of production equipment, and also modernized the infrastructure for unloading corn. Work has also begun on extending the grain elevator line, which will create a natural barrier to the sound generated at the plant.

Inne aktualności